Proportional value of functional groups in forming machines

Canadian Property Valuation Magazine

Search the Library Online

By Roman Šůstek, Ph.D., an expert in forensic economics who deals with property valuation in Czechia (formerly the Czech Republic).

Note: This article was prepared for the purpose of solving problems in assessing the technical condition of forming machines (e.g., presses, bending machines, etc.) and determining their total value. It is related to the article entitled Comparative Analysis of Pricing Parameters published in Volume 67, Book 1, 2023 of Canadian Property Valuation.

Experimental derivation of functional groups

of forming machines and their proportion to the whole

Forming machines differ in their use, design, and essential parameters. The design of a given forming machine depends on the type of forming operation it undertakes and the product it subsequently produces.

That stated, forming machines consist of different structural groups, which, at lower hierarchical levels, are made up of components and parts. Quantification is the process of determining the value of the components of a machine as a percentage of the total value. To give a fictional example, if the total value of a machine is $1,000, and the drive makes up 10% of that amount, the drive would be valued at $100.

In view of the variability of forming machines, and for the purposes of valuation, it seems appropriate for appraisers to follow a uniform breakdown of their structure and quantification. We can do this by considering the components of forming machines according to their functionality and thus subdivide them into ‘functional groups’ using four categories: mechanics (stand), mechanics (components), hydraulics, and electrical.

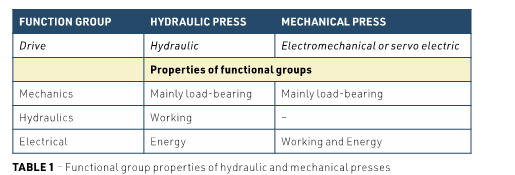

The structural breakdown of two typical press forming machines with hydraulic and mechanical drives is shown in Table 1.

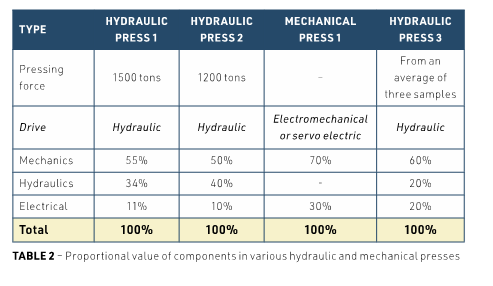

To author this article, the leading manufacturers of forming machines in Czechia were contacted to provide information concerning the proportional value of these functional groups in relation to forming machines as a whole. Thus, the relative proportions of each functional group shown in Table 2 are based on detailed price calculations of three hydraulic presses and one mechanical press, each produced by different companies. This is proprietary information, so the production companies are not identified in relation to their products.

In the case of the hydraulic presses, the proportional value of the mechanical components decreases with decreasing tonnage, the proportional value of the hydraulic components increases slightly, and the proportional value of the electrical components remains the same.

In the case of the mechanical press, the working components are classified within the ‘mechanical’ and ‘electrical’ groups. It is clear from this analysis that the proportional value of the functional groups is influenced by both the type of drive of the forming machine and its tonnage.

Other valuation considerations for forming machines

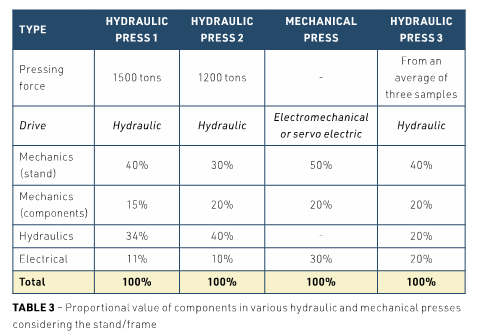

The lifespan of a forming machine depends on the service life of its components. Thus, in appraising a machine, it is important to consider the service life of the supporting parts such as the machine stand or frame. This component usually has a long service life and can typically be renovated with simple surface treatments like welding. However, in making repairs to machine stands/frames, the dynamic stability of the machine must not be disturbed.

In many cases, a forming machine can be completely modernized simply by replacing some structural components. This extends the overall service life of the machine.

The proposed breakdown of the forming machines and the proportions of their functional groups considering the service life of the supporting frame is given in Table 3.

Functional groups for selected forming machines

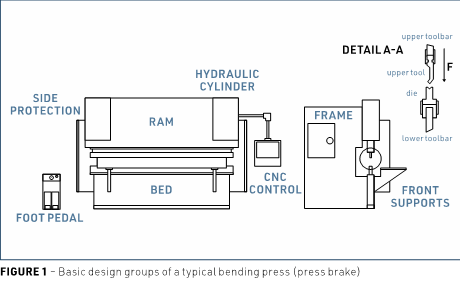

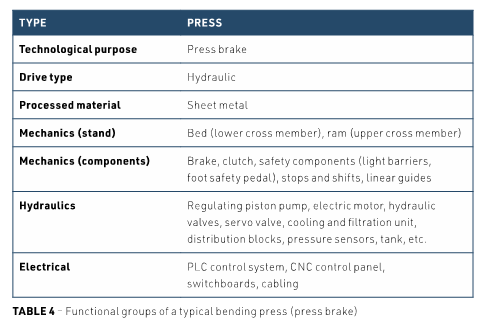

The division of forming machines into functional groups of mechanics (stand), mechanics (components), hydraulics, and electrical is shown in Figure 1 on a bending press.

The functional groups of a typical bending press (press brake) are listed in Table 4.

Conclusion

Grouped by their functionality, we can categorize forming machine components as follows: mechanics (stand), mechanics (components), hydraulics, and electrical. Such a breakdown is simple and fully corresponds to appraisers’ needs in identifying, assessing, and evaluating the residual service life of these machines.

The proportional value of each functional group is based on detailed price calculations. For example, when pricing a hydraulic press, the mechanical (stand) accounts for 30-40% of the total value, whereas the mechanical (components) account for 15-20%, the hydraulic components account for 20-40%, and the electrical components account for 10-20%. These proportional values of the functional groups may be used as a guide in valuation for all forming machines, though, in order to be accurate, they must take into consideration the tonnage and drive type of the given machine.

Note: This article is based on the author’s PhD thesis entitled A System Approach

to Valuing Forming Machines (available from https://www.vut.cz/en/us). The proportional values of the different components of the hydraulic and mechanical presses were provided by the leading manufacturers of forming machines in Czechia; ŽĎAS, a.s. and Dieffenbacher CZ hydraulic presses, s.r.o.